PF Ultrasonic Technology Will Replace The Traditional Way Of Doing The Screening!!

We are always working hard and trying to make the best products for you. Feel and enjoy!

WE WELCOMES YOU WITH

"PF Ultrasonic" is the new venture of the Old Players in the field with new Sieving technology and touch of Ultrasonic vibrations. The Vibrations can also be felt in the entire crew of the Company. The Company has entered an untouched field of opportunity and possibilities.

The Ultrasonic Vibratory Sieving Machine is the latest development of the Company with clear vision to develop it completely Indigenously. We really take proud to develop such a Quality Product that will serve many in the Industry.

The Company situated in the Heart of Gujarat, Rajkot City with Ultra Modern facilities and State of art Machineries to develop the Quality Product that stands tall in front of the World class manufacturers.

The depth analysis and micro accuracy in the production and pre production stage has earned us the status from where we can deliver the best each and every time.

The new Technology of Ultrasonic Vibratory Screen will completely replace the traditional way of doing the screening. It's evenly transmitted oscillating motion reduces the friction between sieve and Separation material to increase the Quality of Your Sieve and even life of the Screen. It also leaves an additive effect on the screen so as the Material Blockages are minimised and saves the time of Output volume.

The Sieving Technology with Ultrasonic factor added to the Screen helps in great way due to very quick Oscillation and frequency. Because of the higher Oscillation and Frequency there is minimal of friction between Screen and the Material which results in lower blockage and higher production rate. The benefit is seen in accuracy as well and You get the same size particles of Your end product.

Here Are Specification Of Sieving Technology

System Components For The Sieving Technology

Ultrasonic Screen Attachment is designed in such a way that it can easily be used with all existing commercial sieving equipment.

Ultrasonic Screen Attachment system consists of following components:

Ultrasonic Generator: It is a complete electronic unit. It can be attached directly to the sieving machine or can be placed around it.

Ultrasonic Sieve Resonator: It Consists of a converter with ring resonator which are connected to the sieving frame with mounting plates.

Electrical connection: It comes with housing, plug and 3 meter long cable.

Increases capacity - Ultrasonics can improve sieving capacities by up to 10 times by enabling powders to pass through screens faster

Reduces production downtime - Prevents screen overload and requires a lower frequency of mesh cleaning

Improve your product quality - Sieve on finer meshes (as low as 20μm) and obtain a better quality final product

Lowers running costs - Reduces mesh damage and the need for repairs and replacement mesh caused by mechanical deblinding systems

Superior accurate separation efficiency

Less maintenance and power consumption

Lower noise levels

Ball tray for anti-blocking

Simple & compact construction

Reduced labor costs and wastage

| No | Specification and components details | PF Plus |

| 1 | Input Supply | 220 VAC, 50 Hz. |

| 2 | Ultrasonic Power Output | 100 Watts, Continuous and pulse mode |

| 3 | Frequency | 33 kHz |

| 4 | For your existing vibro-shifter Diameter | 8” to 60” and above |

| 5 | Detachable Converter | Screwed to the ring resonator |

| 6 | Ultrasonic Attachment | To be welded on vibro-shifter mesh frame |

| 7 | HF Cable Length | 5m and 10m long |

Pharma an Metal Powder Industry

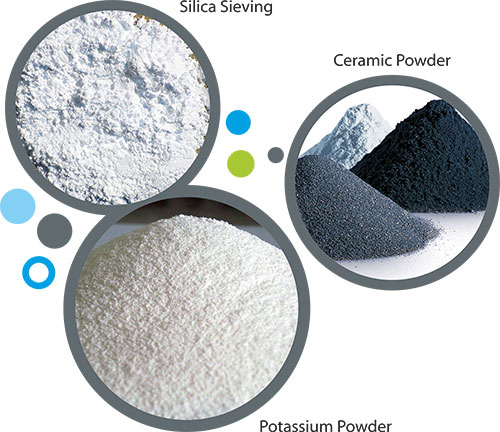

It has a wide area of applications that touches various Industries like Powder Coating, Pharmaceutical & Herbal Medical Industry, Chemical Industry, Dies, Tooth Powder, etc...

Abrasive and Ceramic Industry

The Other Industrial application includes Abrasive Industrial Powder, Graphite, Iron & Zinc Powder, Iron Aluminum & Zinc Oxides, Nickel & Nickel Alloy, Potassium Powder, Tungsten & Tungsten Alloy, and many more...

TIMELESS. DISTINCTIVE. BEAUTIFUL.

Feel Free To Contact Us. We Would Like To Here From You.!!

G-Road, Lodhika G.I.D.C.,

Kishan Gate Road,

Metoda - 360021,

Rajkot (Gujarat) India.

+91-98254-88359

+91-98251-21474

+91-98252-66530

pf@ultrasonic.com

www.pfultrasonic.com